We are on track to save

1 gigaton of CO2 by 2040

8%

of global emissions come from the cement industry—World Economic Forum

80%

of concrete emissions come from cement production—World Resources Institute

2nd

Cement is the second-most used commodity after water—MIT

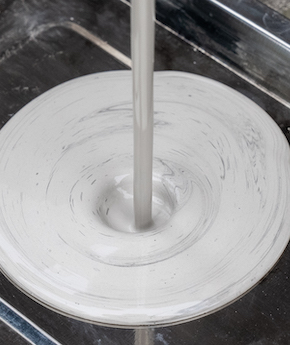

Our technology

Rethinking cement

Proprietary Alkali Fusion®

Our alkali fusion process creates a superior clinker-like material under ambient temperatures, drastically reducing carbon emissions.

AI-Powered Innovation

We use advanced AI to accelerate material development and optimise feedstock selection for unparalleled performance.

R&D Machine

We collect data at every step in our value chain, learn from our customers and partners and leverage the power of AI and machine learning to continuously improve our processes.

Efficient factories

We partner with our customers to design and build compact factories. They’re the small-footprint, big-impact units for our scalable operations and allow for sustainable, high-volume production.

Sustainable production

We carefully consider our supply chain and factory locations to minimise our carbon footprint. By siting our factories close to raw materials and end markets, we reduce transportation emissions and optimise efficiency.

Innovative manufacturing

We are pioneering a new wave of factory operations that embody the art of engineering. Our lean, highly automated facilities are designed for maximum efficiency.

Transforming abundant byproducts into feedstocks

By mapping and understanding the waste generated across sectors, we’re building the foundation for a circular economy, turning industrial byproducts and abundant natural materials into valuable resources. Cleaning up the world requires collective action, and we are committed to working together to drive meaningful change.

Identifying the right materials

We leverage AI to identify the right materials for each application – whether wastes, industrial byproducts, or abundant natural materials not otherwise utilised. Our approach ensures sustainable and efficient production to create superior products for our customers.

Eco-friendly materials

We champion industrial byproducts, wastes and abundant natural materials to create eco-friendly cement, reduce landfill waste and promote circularity. By repurposing byproducts from processes like steel manufacturing, we help industries minimise their carbon footprint and get closer to waste-free operations.

Proprietary Alkali Fusion®

Our alkali fusion process creates a superior clinker-like material under ambient temperatures, drastically reducing carbon emissions.

AI-Powered Innovation

We use advanced AI to accelerate material development and optimise feedstock selection for unparalleled performance.

R&D Machine

We collect data at every step in our value chain, learn from our customers and partners and leverage the power of AI and machine learning to continuously improve our processes.

Efficient factories

We partner with our customers to design and build compact factories. They’re the small-footprint, big-impact units for our scalable operations and allow for sustainable, high-volume production.

Sustainable production

We carefully consider our supply chain and factory locations to minimise our carbon footprint. By siting our factories close to raw materials and end markets, we reduce transportation emissions and optimise efficiency.

Innovative manufacturing

We are pioneering a new wave of factory operations that embody the art of engineering. Our lean, highly automated facilities are designed for maximum efficiency.

Transforming abundant byproducts into feedstocks

By mapping and understanding the waste generated across sectors, we’re building the foundation for a circular economy, turning industrial byproducts and abundant natural materials into valuable resources. Cleaning up the world requires collective action, and we are committed to working together to drive meaningful change.

Identifying the right materials

We leverage AI to identify the right materials for each application – whether wastes, industrial byproducts, or abundant natural materials not otherwise utilised. Our approach ensures sustainable and efficient production to create superior products for our customers.

Eco-friendly materials

We champion industrial byproducts, wastes and abundant natural materials to create eco-friendly cement, reduce landfill waste and promote circularity. By repurposing byproducts from processes like steel manufacturing, we help industries minimise their carbon footprint and get closer to waste-free operations.